Sugar

Sweetening the Sugar Manufacturing Process

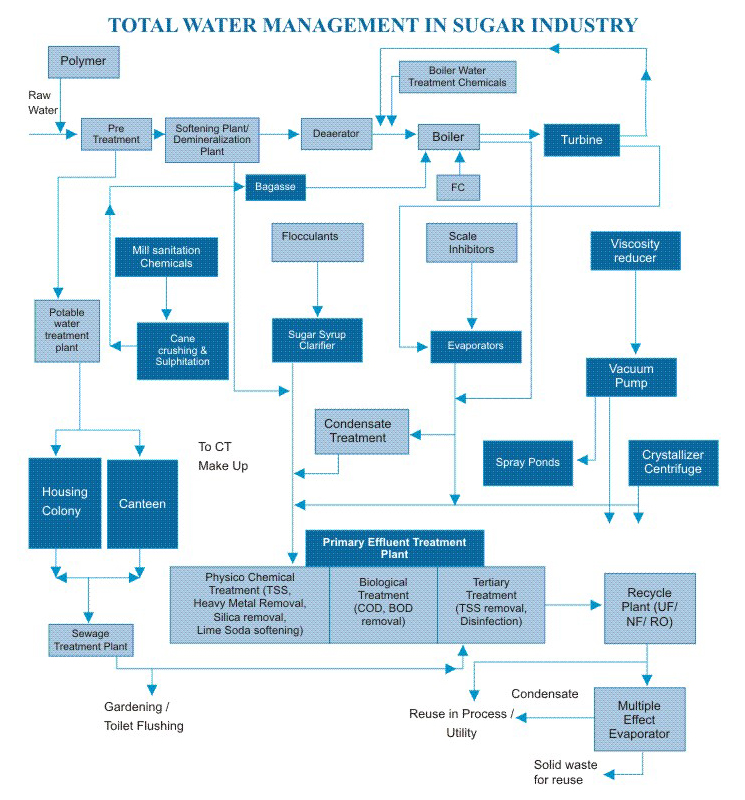

We offer total water and environment management for sugar mills and their cogen plants; we also offer a complete range of high performance speciality process chemicals specially developed for diverse applications in liquid and solid sugar manufacture.

Water Management:

Pretreatment

Process water treatment

Boiler and cooling water chemical treatment programmes

Waste water treatment & recycle to achieve zero discharge

Sugar condensate recovery

Comprehensive O&M and AMC of the total water circuit

Upgradation /retrofitting plants on BOT basis

24/7 service support

Supply of consumables like ion exchange resins, membranes, adsorbents, water treatment chemicals and antiscalants; supply of critical spares

Total water management consultancy

Sugar Remelt Ion Exchange Decolourising Process

Apex Chemicals offer INDION resins for decolourisation of sugar melt. This ion exchange process has synergistic effect with phosflotation and carbonation and operates by passing the pretreated sugar melt through a combination of speciality ion exchange resin columns. On crystallisation the final colour of the sugar is in the range of 20 – 40 ICUMSA units and qualifies as EC Grade 2 sugar. It opens avenues for exports of quality sugar by the sugar industry; and reduces the need for the confectionery, beverage industries to import high quality refined sugar.

Speciality Process Chemicals

Mill sanitation chemicals

Sugar enhancer

Flocculants

Scale inhibitors

Viscosity reducers

Colour precipitants

Flotation aids

Boiler & cooling water treatment chemicals

Bagasse/Fuel additives

Activated carbon